Replacement conductors shall be of the same voltage and current rating as the original conductor. Western Union splices are used for solid conductors.Ĭable ties/lacing shall not be installed across the splice/solder sleeve body, unless sufficient protection is provided to prevent compression damage to the termination and/or to the insulation of adjacent conductors. Tubing is tightly shrunk, with proper strain relief, overlap and no exposed conductive surfaces. The termination is fully wetted, smooth and shiny. Tubing is tightly shrunk with proper strain relief, overlap and no exposed conductive surfaces. Tubing is tightly shrunk with proper strain relief.

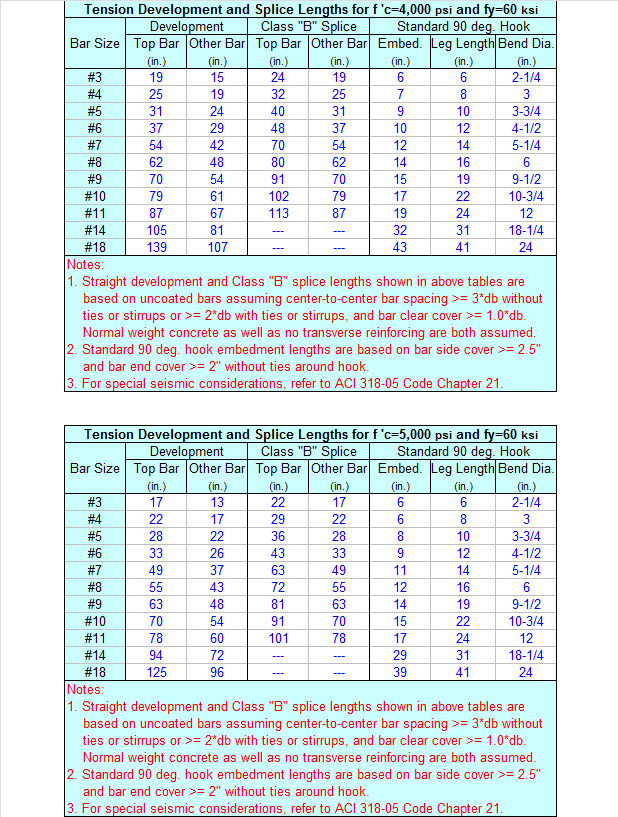

The termionation is fully wetted, smooth and shiny. Conductor(s) exhibit proper bend radius and strain relief. Overlaps meet minimum electrical spacing, while providing strain relief. Indents are symmetrical and centered on the crimp barrel. The contact has been deformed only by tool indenters. Final assembly profile shall not impact form, fit or function.Ĭable ties/lacing shall be installed at both ends of a splice or solder sleeve, but placement shall not violate stress relief requirements. The location of splices shall be staggered to minimize the increase in profile to the harness. The splice exhibits a smooth profile, proper strain relief, and is located in an area of the harness not subjected to flexure. See Section 4.01 "Cable and Harness, General Requirements", and Section 6.01 "Through-Hole Soldering, General Requirements", for common accept/reject criteria. Bar laps should be securely wire-tied together to maintain the alignment of the bars and to provide minimum concrete cover.CABLE AND HARNESS SPLICES CABLE AND HARNESSĪ splice is the joining of two or more conductors together in a manner that results in a permanent electrical termination and mechanical bond, and may be completed by either crimp or solder process. The length of lap should be increased 20% for a three-bar bundle and 33% for a four-bar bundle. Lap splices of bundled bars should be based on the lap splice length recommended for individual bars of the same size, and individual splices within the bundle should not overlap each other. Lap splices of #14 and #18 bars should not be used, except in compression only to #11 and smaller bars. When bars of different sizes are lap-spliced in compression, the lap splice length must be the larger of the compression development length of the larger bar or the compression lap splice length of the smaller bar. Where reinforcing bars of two sizes are lap-spliced in tension, industry practice is to use the larger of the tension lap splice length for the smaller bar, or the tension development length for the larger bar.

#Lap splice code

Non-contact lap-spliced bars should not be spaced too far apart.įor lap splice design and construction, the ACI 318 Building Code requires the engineer to indicate locations and lengths of all lap splices on the structural drawings. CRSI's Reinforcement Anchorage and Splices includes tables of required lap splice lengths based on these variables.Ĭontact splices-in which the bars touch and are wired together-are preferred because they are more secure against displacement during construction. The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. Detailer Training Program (Fabricator Member)Ī lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar.Hydraulic Shear Safe Operating Procedure.Trailer Fall Protection General Safety Awareness.Alligator Shear Safe Operating Procedure.Automatic Coil Bender Safe Work Procedure.

#Lap splice full

Radius Bending Safe Operating Procedure Tensile tests on lap splice fillet welded joints in 410C grade reinforcing steels have shown that matching strength to full bar strength is achieved at a.Water Resources Development Act (WRDA) Reauthorization.In such a lap splice, two culms are overlapped by at least one internode and lashed together at two or three locations. 20.26 (a)) are the most basic type of this connection ( Jayanetti and Follet, 1998). Surface Transportation 5-Year Reauthorization Traditional joining methods rely principally on lashing (Group 3) with or without dowels (Group 4B) lap-splices ( Fig.Environmental Product Declaration (EPD).Stainless Steel Fabricator Certification.

0 kommentar(er)

0 kommentar(er)